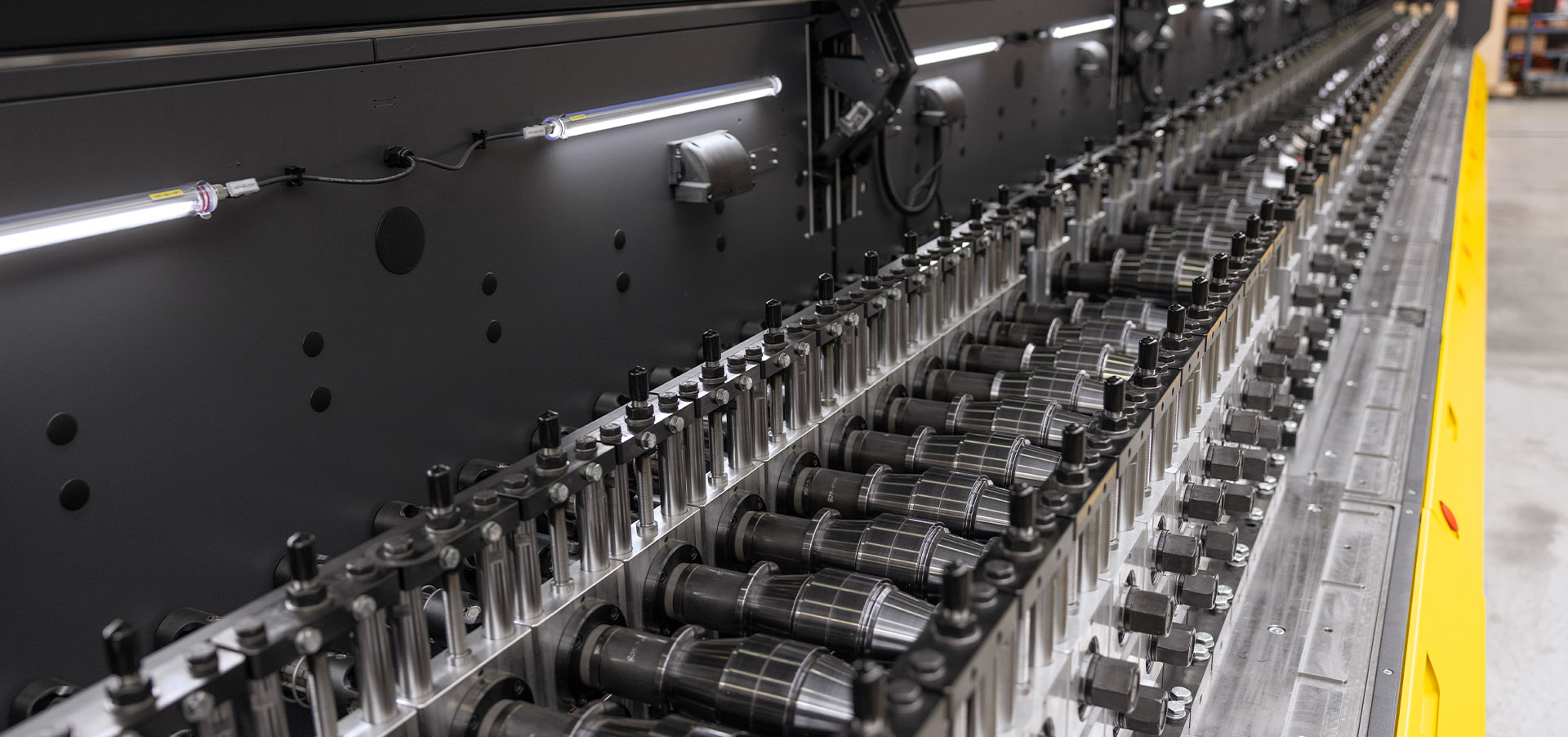

Profiling or roll forming describes the forming of ferrous or non-ferrous metals in successive forming stages (roll forming stands) to produce a finished profile with the desired cross-section. The tools used here are rollers with the appropriate geometries, which gradually shape the sheet metal strip. Roll-formed profiles have clear advantages over extruded and folded profiles. Profiling by roll forming is fast, economical and variable. It is also possible to process high-strength and ultra-high-strength materials and production is more environmentally friendly. High processing accuracy and low tolerances ensure that the workpiece can also be processed very well automatically. Even coated and painted sheet metal can be processed without damage and with maximum precision. In addition, desired material properties can also be enhanced in the roll forming process: in the case of a heat conducting sheet for solar collectors, the absorption properties are even optimized by roll forming on our roll forming systems. In this way, the finished solar collector achieves greater energy efficiency through even better heat transfer to the energy source.

Coating refers to the application of materials, paints, varnishes or films to a substrate. The forming processing of coated materials in particular poses many challenges in terms of handling and the entire production process. For products in the visible area, for example, the appearance of the surface in terms of freedom from scratches and gloss is of great importance and is reflected in customer satisfaction. Profiles can also be customized by coating. Contact us for individual and process-integrated coating and decoating solutions in your production facilities. We will be happy to implement the right process for you.

Automation and digitalization are playing an increasingly important role in the efficient design of production facilities. It describes the transition from independent manual production steps to networked processes and machine-supported work procedures. The seamless process and the "meshing of all gears" should be achieved through the integration of control and regulation options. This not only reduces the workload for people, but also creates planning reliability and efficiency. Profiling 4.1 - At XELLAR, the focus is on people. The one stands for the people who enjoy working successfully with our roll forming systems. Because in the end, profiles are as good as the synergy between man and machine. That is smart profiling!